Taking care of machines is like giving them regular check-ups to keep them happy and running smoothly, making sure they don’t take unexpected breaks. Machine maintenance involves sticking to a schedule, doing routine checks, and fixing things before they become big problems. It’s like getting a new tire when yours is getting too worn or fixing something that’s not working quite right.

Every place with machines, like factories or big buildings, needs machine maintenance to stay on track. It helps them stick to their plans, avoid long breaks when things stop working, and make sure everyone stays safe. So, taking care of machines is like keeping everything running smoothly and avoiding big troubles.

Types of machine maintenance

There are eight ways to take care of machines, and each way has its good and not-so-good points (except for reactive maintenance – that’s just not great at all). You can mix and match these methods to make a smart plan for keeping everything running smoothly.

1. Reactive Maintenance

This is like trying to put out a fire after it starts. It’s not planned, it’s a surprise, and usually, you have to hurry to fix things.

2. Run to Fail Maintenance

This is a bit like waiting for a toy to stop working before doing anything about it. But here, it’s on purpose. We have a plan to get it fixed or replaced quickly when it decides to take a break.

3. Routine Maintenance

Routine maintenance is like giving our things a regular check-up. It involves simple tasks, such as looking, testing, putting some oil where needed, and changing parts that are old or not working well. We do these tasks regularly, as part of a plan, to keep everything running smoothly.

4. Corrective Maintenance

Corrective maintenance is about fixing things before they completely stop working. It’s like when we notice a small problem and quickly do something about it to prevent a big problem later. For example, during a check-up, we might notice something a bit off and fix it right away, so everything stays in good shape.

5. Preventive Maintenance

Preventive maintenance is like giving a check-up to machines before they get sick. There are two main types: time-based and usage-based. Time-based means doing tasks at specific times, like every month or every 10 days. It’s like putting a date on the calendar to make sure everything’s okay.

Usage-based is when we check machines based on how much they work. It’s like taking your car to the mechanic after driving 500 miles or finishing 15 rounds of making stuff. Both ways, we make sure things keep running smoothly.

6. Condition-Based Maintenance

Fixing things when they start acting up! Condition-based maintenance is like checking your car regularly to see if it’s running smoothly or needs a little love. We use inspections, data, or tests to figure out when it’s time for a tune-up. It’s like giving your assets a check-up to catch problems early.

7. Predictive Maintenance

Staying one step ahead! Predictive maintenance is like having a superhero sense for your machines. We use tools and sensors to keep an eye on them in real-time. This way, we can spot issues before they turn into big problems. It’s like fixing your car before it even thinks about breaking down.

8. Prescriptive Maintenance

Prescriptive maintenance is like having a super-smart assistant for fixing things! Instead of waiting for stuff to break, it uses fancy tech like machine learning and artificial intelligence. Imagine sensors keeping an eye on machines all the time, and this smart system tells you exactly when and what maintenance is needed. It’s like having a helpful friend who knows when your car needs an oil change before you even realize it.

Four ways to improve machine maintenance

Improving machine maintenance at your place boils down to four main things: Planning, precision, protection, and measurement.

1. Planning

Make a plan for taking care of machines. This means making sure you have all the parts, tools, and people ready when they’re needed. It’s like having a game plan to use everything wisely. The plan includes two types: scheduled checks to catch problems early, and unscheduled fixes to get things working again ASAP when they break. It’s all about being ready and not waiting for things to go wrong.

2. Precision in Maintenance

Making sure things work smoothly is like creating a perfect recipe. To keep everything running just right, we need a precision maintenance strategy. This means doing maintenance tasks in the best way possible, like following a recipe step by step.

For this to work well, we need four important things:

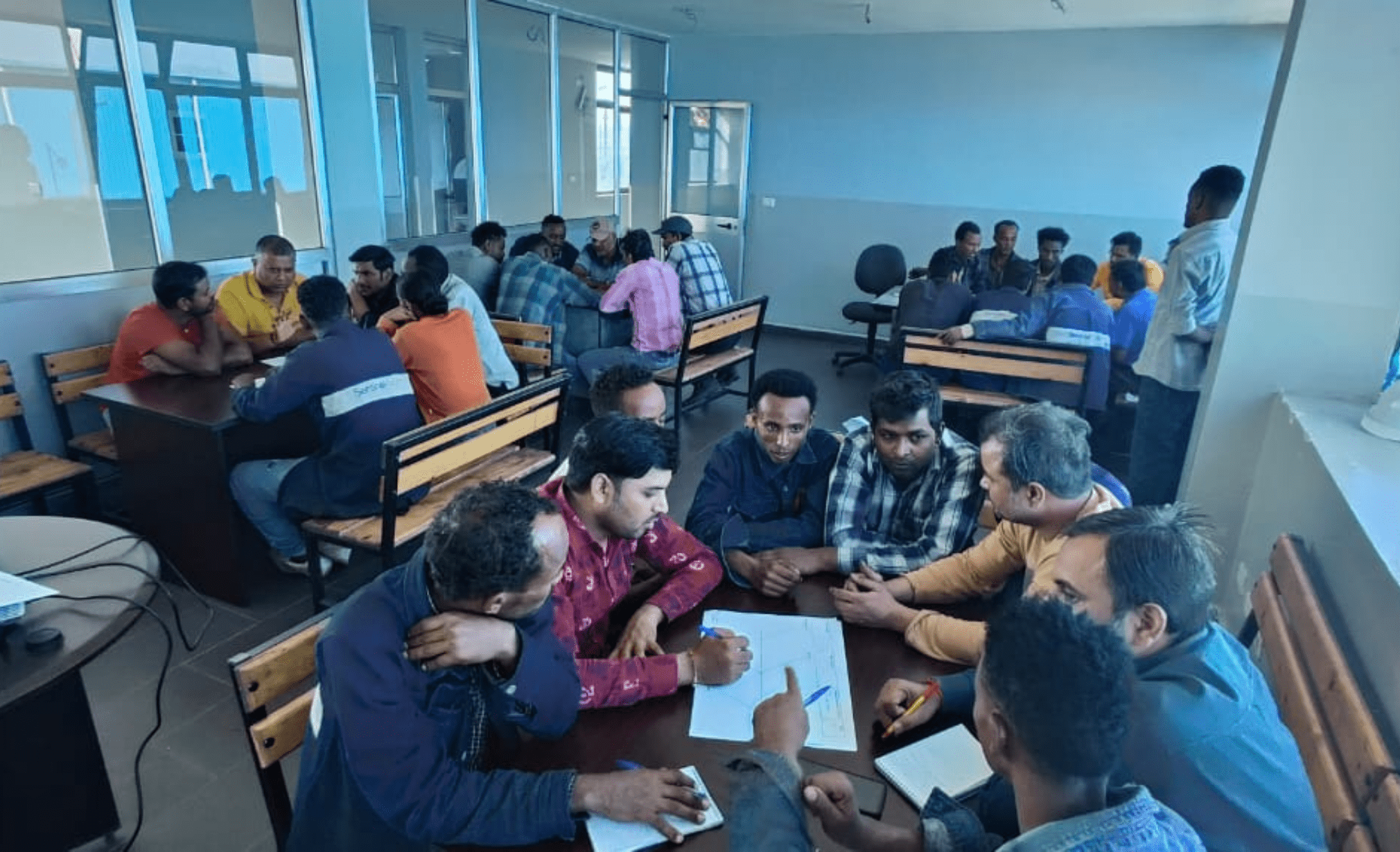

- Trained Workers: People doing the maintenance need to know exactly what to do. It’s like having chefs who know the recipe inside out.

- Tools Ready to Go: Imagine cooking without the right tools. It’s the same with maintenance. Having the right tools and equipment ready is super important.

- Top-Quality Materials: Just like using good ingredients in cooking, maintenance materials must be top-notch. No contamination allowed!

- Easy Plans: Following a recipe is easy if it’s written well. Similarly, maintenance plans and steps must be simple and accessible so everyone can follow them without any confusion.

By getting these four things right, we’re like chefs in the kitchen – making sure everything works perfectly every time!

3. Protection

Making things work better also means keeping everyone safe. To do that, the people doing the job need the right safety gear and need to know how to use it.

Here are a few important things to do to make sure everyone stays safe:

- Check a lot to make sure the guards or barriers are there and not broken.

- Look closely at electrical stuff like wires and switches to make sure they’re not showing.

- Make sure everyone knows how to stay safe at work by giving them regular safety training.

4. Measurement

The last part of the machine maintenance puzzle is keeping track of how well things are working. It’s like checking the score in a game. Without this information, plans to fix machines before they break won’t be effective. Knowing exactly how your machines are doing helps you pick the best way to keep them working well. It’s like having the right playbook for a winning game, ensuring everything runs smoothly and reliably.

Why is Machine Maintenance Important?

Taking care of machines is super important for everyone who uses them in a company. That’s why it’s a must to have a plan to keep the equipment in good shape. Depending on what kind of machines you have, the best plan will include different types of maintenance. Figuring out the perfect balance might not be simple and will take some time, but the result will be machines that work better, a team that gets more done, and fewer problems that cost money.

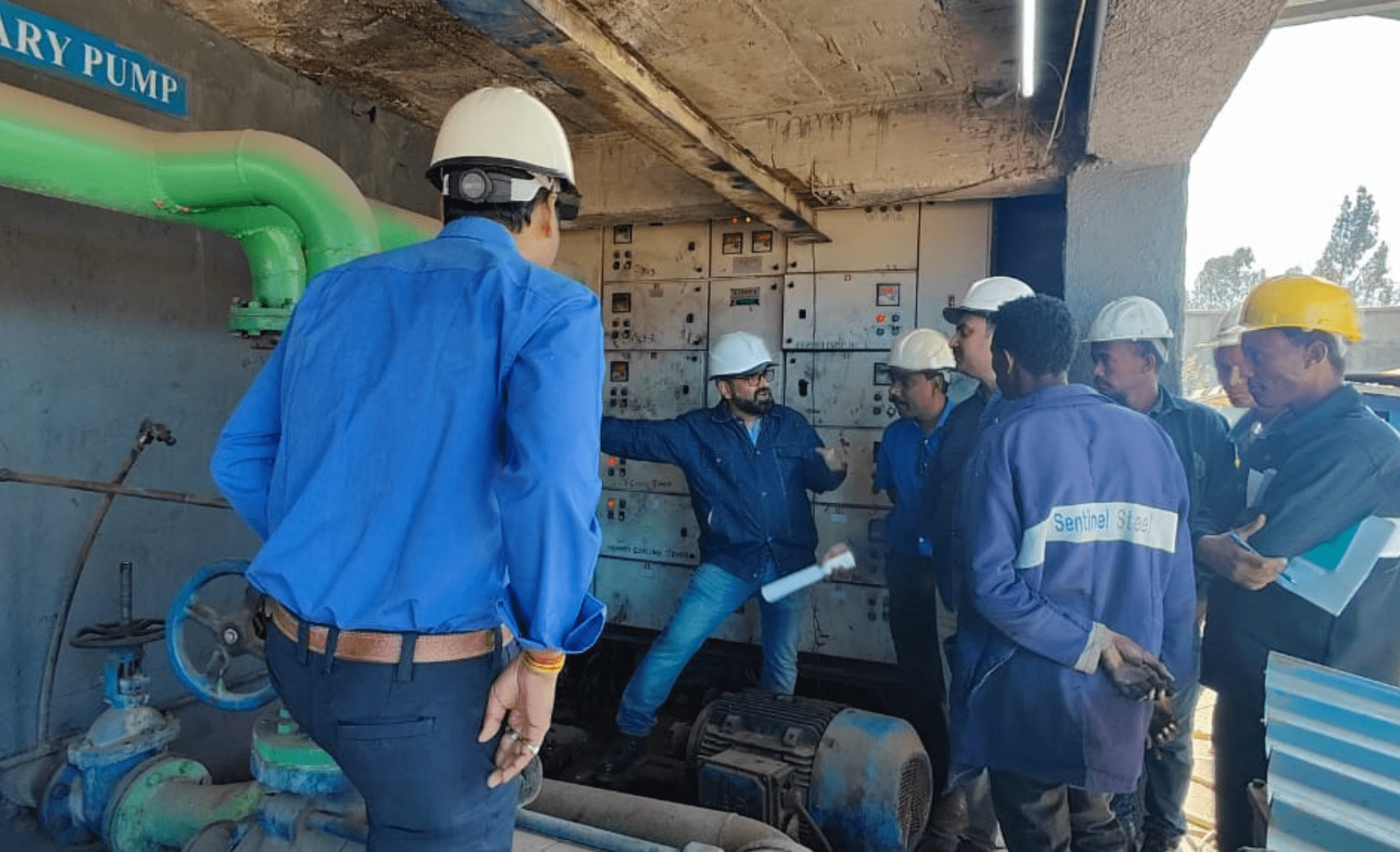

Key 9 out of the 20 keys is all about making machines and equipment work better. The idea is to get the people who use the machines every day, like operators, to be part of keeping them in good shape. This means doing small checks and tasks every day to prevent issues and using the equipment the right way. The maintenance experts focus on planning the overall strategy, and everyone works together to keep things running smoothly. It’s like a team effort to make sure the machines stay effective.

One way to make this process even better is by using a performance management system like the one offered by Gemba PMS. This system helps you keep track of how well everything is working and lets you plan ahead. It’s like having a smart tool that guides the team in doing the right tasks at the right time, making sure the machines stay top-notch.