Introduction

The poultry industry, integral to global food security, faces unique challenges in its rapid expansion,including variations in feed usage, high mortality rates, and issues with stocking density and feed cost.

Addressing these efficiently is crucial for the industry, known for its high volume and fast-paced environment, to maintain its competitive edge and sustainability

The Imperative of Operational Excellence

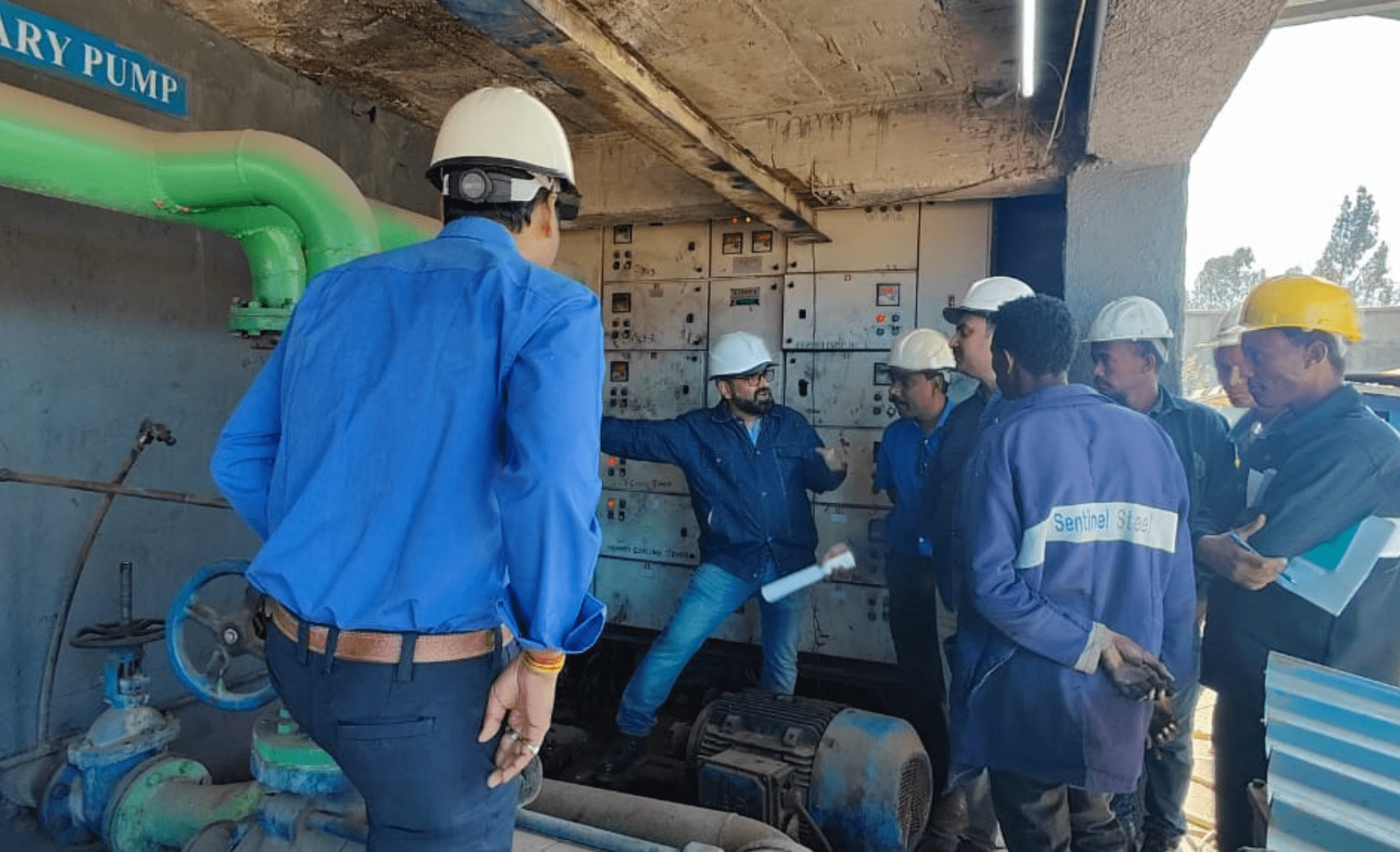

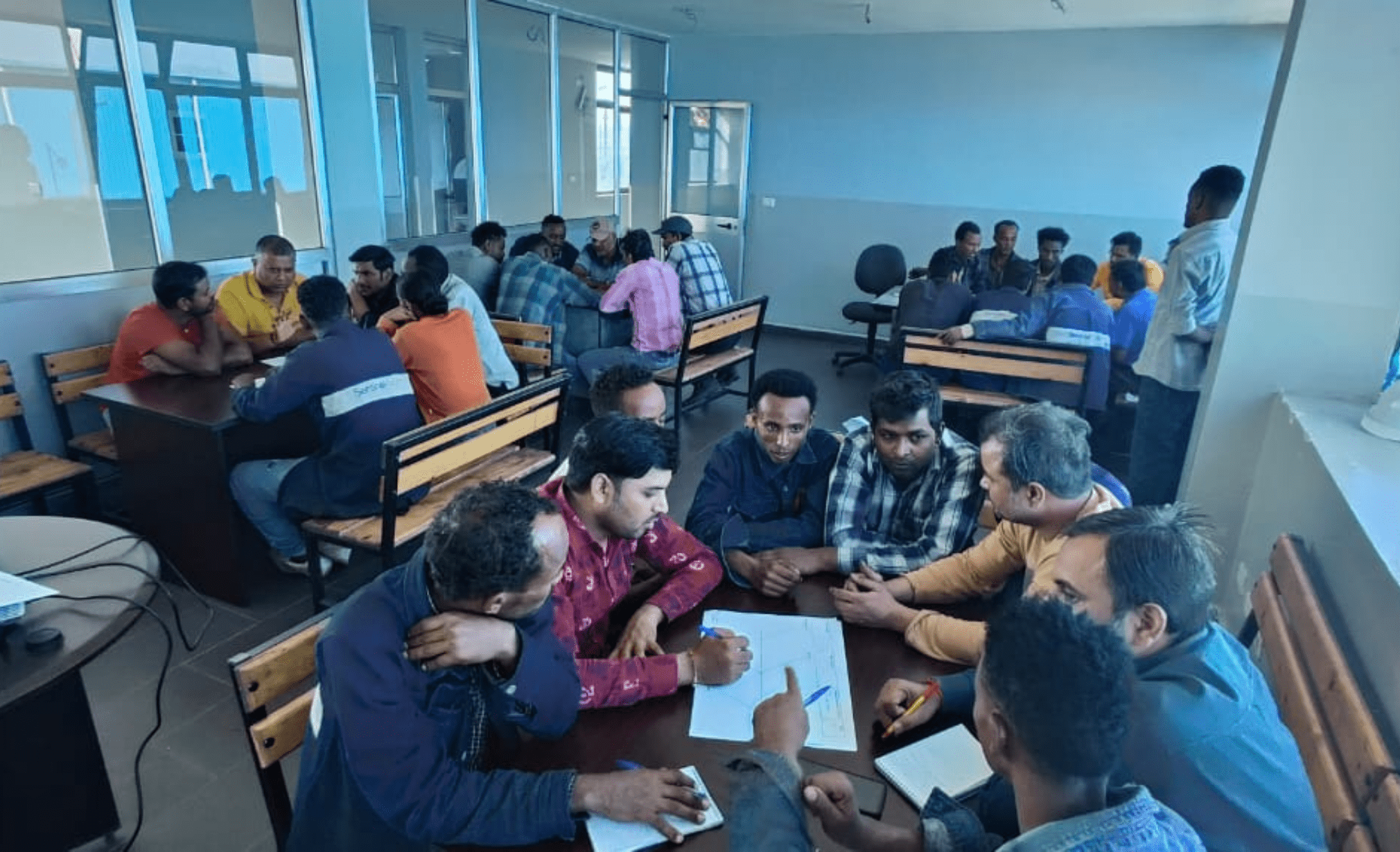

Operational excellence is vital in the poultry industry, central to achieving increased efficiency, waste reduction, and enhanced product quality. In light of environmental concerns and economic pressures, adopting the 20 Keys methodology is essential. It addresses the industry’s specific challenges, optimizing processes to improve feed efficiency, reduce mortality rates, and enhance production output. This approach ensures poultry businesses can adeptly manage costs and maintain high-quality standards while ensuring employee safety and satisfaction.

Success Metrics Aligned with QCDSM in the Poultry Industry

The application of the 20 Keys in poultry operations leads to substantial improvements:

Q-Quality Management

.

- Improvement in hatchability rates, ensuring robust and healthy poultry output.

- Reduction in mortality rates, indicating better health and living conditions for the poultry.

- Enhanced product quality, leading to increased customer satisfaction.

- More efficient feed usage, reducing one of the largest operational costs in the industry.

- Reduction in mortality rates, which translates to lower costs and less resource wastage.

- Improved stocking density and feed cost management, optimizing resource use and operational

expenses.

C-Cost Efficiency

.

D - Delivery and Output Optimization

.

- Increased output per kilogram, maximizing the yield from each bird.

- Optimized inventory management, leading to a more efficient supply chain and storage capacity

utilization. - Improved feed consumption ratio, enhancing the overall efficiency of the production process.

- A safer, healthier environment for the poultry, reducing risks and enhancing welfare standards.

- Improved morale and engagement among employees due to better workplace conditions and a

sense of contributing to sustainable practices. - Enhanced operational safety standards, protecting both the workforce and the poultry.

SM - Safety and Morale Advancements

.

Additional Strategic Advantages

.

- Ease of Certification and Audit Compliance: Implementing the 20 Keys helps in meeting industry standards and regulations with ease, crucial for certifications and audits.

- Long-term Organizational Benefits: The sustained improvements in processes and systems contribute to the long-term resilience and growth of the poultry business.

Conclusion

For managers and executives in the poultry industry, adopting the 20 Keys framework with Gemba PMS translates into a strategic partnership deeply aware of the sector’s specific needs. Our approach ensures impactful implementation for significant return on investment. With our expertise, we guide you on this journey, transforming your poultry operations into a model of efficiency, quality, and sustainability, setting a benchmark in the industry.