The great explorer of the truth, the master-builder of human happiness no one rejects dislikes avoids pleasure itself because it is pleasure but because know who do not those how to pursue pleasures rationally encounter consequences that are extremely painful desires to obtain.

Read MoreWho We Are

Gemba Performance Management System (Gemba PMS) is a Kenya-based consulting company with 25 years of experience in practicing and successfully implementing world-class continual improvement methodologies in different (medium and large) companies with a strong understanding of the East African industrial work environment.

What we do

In today’s business environment, it doesn’t matter where we are located and the kind of business you are doing; there is no doubt that you will face local and global economic challenges & competition in your industry. To perform in such a competitive & challenging environment, we must continuously improve our operational performance in 360 degrees.

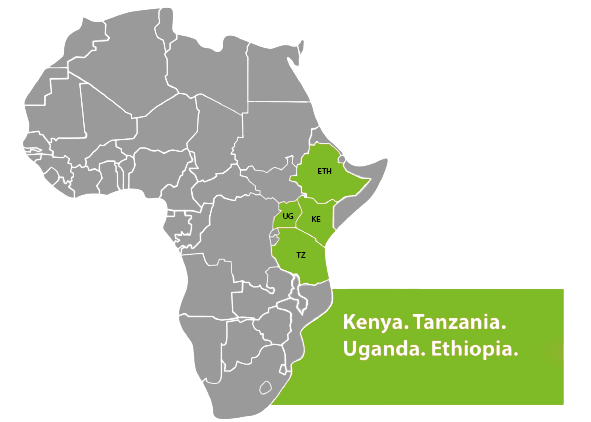

Gemba PMS is the exclusive license holder with the Practical Program Of Revolutions in Factories (PPROF) from Japan to practice & implement 20 keys philosophy and thinking processes in Eastern Africa (Kenya, Tanzania, Uganda & Ethiopia) countries.

We are also well aligned with our strategic business partners globally to provide the best in industry service and real-time solutions to organizations who aim to align themself in the journey of continual improvement to achieve Operational Excellence.

Working with a perfect method is the only way to achieve perfect results.

Our Method

Today globally, several organizations are on the journey to achieve operational excellence. We can see that some of them are performing very well, achieving the desired results, and moving in a positive direction. However, some organizations still face challenges and struggle to improve their performance even if they work hard and practice various continual improvement methods. These organizations face (Quality, Cost, Delivery, Safety & morale, and Technology) related performance challenges.

What are the critical factors in success and failures in any organization’s operational excellence journey?

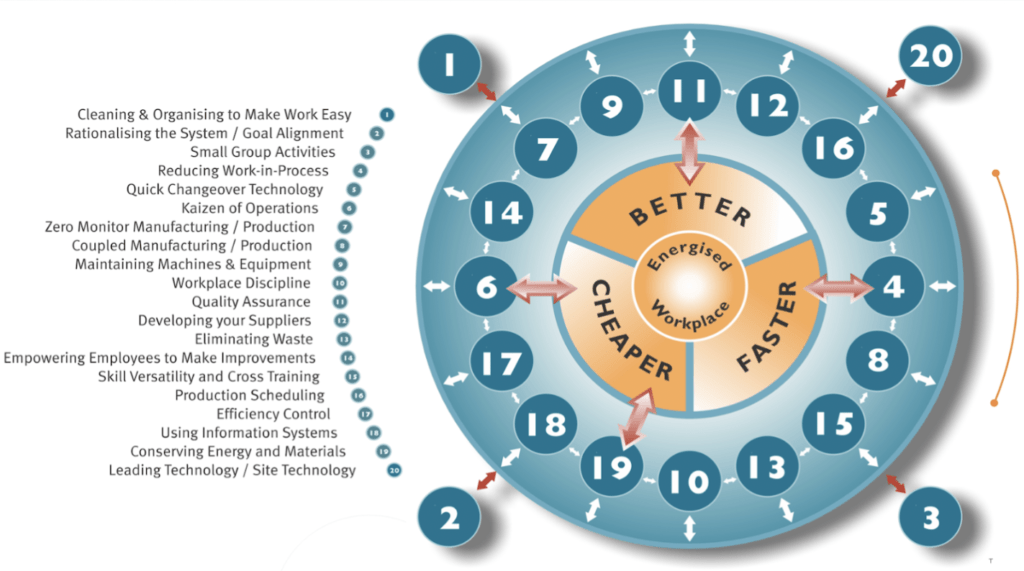

GembaPMS comes with a holistic world-class continual improvement method with 20 keys, a philosophy, and a thinking strategy designed by Iwao Kobayashi. Many world-class organizations consider it a vehicle of continual improvement that moves your organization forward in the journey of Operational excellence.

Our Approach

Our approach is simple and well aligned with your operational requirements.

We understand that every organization has unique processes and challenges. It requires a focused continual improvement approach aligned with its business structure and strategic requirements. Gemba PMS believes in providing SMART customized solutions to maximize operational efficiency and customer satisfaction.

Gemba is the path to continuous improvement

Gemba (現場) is ‘the real place‘; in business, it refers to the actual place where the value created (such as the finance office is a Gemba for the finance team, factory shop floor is the Gemba for production, maintenance & quality team).

Benchmarking yourself against world-class practices

Performance management is the continuous process of improving performance by setting individual and team (Gemba) goals aligned to the organization’s strategic objectives, planning implementation to achieve the goals, reviewing and assessing progress, and developing the knowledge, skills, and abilities of people.

It is possible to establish a highly competitive and result-oriented team only by implementing an effective and holistic Performance Management System across the organization.

Operational performance is the synergy between various Gemba’s with specialized expertise, complementary skills, and the ability to produce excellent output together as a team. All the Gemba’s in the organization collaborate to accomplish specific (Quality, Cost, Delivery, Safety & morale, and Technology) business goals and are also responsible for achieving operational excellence. It is essential for management to introduce & stabilize a holistic method that analyzes and manages the overall performance of each Gemba.

Gemba PMS approach is a more dynamic and SMARTS method. We focus on management target (Less In & More Out) output. This is well defined and aligned with KPI in Q, C, D, SM, and T criteria for every Gemba in the organization to enhance the current work culture to achieve Better, Competitive, and Faster operation every day by everyone.

Your Strategic partners in your journey of Word class.

Gemba PMS believe in working in a dedicated way as partners with our clients to achieve their short & long-term strategic business goals by implementing world-class work practices, rather than working as a short-term event consultant.

A well-proven Japanese method for achieving Operation Excellence

Globally organizations have adopted and practicing 20 keys as their continual improvement work culture to achieve Operational Excellence (improve quality, reduce operational cost, improve delivery, improve safety & morale).

Global Exposer and benchmarking in Operational Excellence practice

A team of professionals working with a holistic approach of Continual Improvement to provide the best in industry service and real-time solutions to organizations who aim to align themself in the journey of continual improvement to achieve Operational Excellence.

Guaranteed ROI:

We ensure a high Return On Investment – ROI (up to 12 times) to our clients, by introducing an effective implementation of short & long-term value-adding (tangible and intangible) practices across the organization (High productivity and quality improvement, reducing operational cost, improving the speed of delivery, improving safety & morale)

Our Expert

Founder & CEO Gemba PMS

Twenty-seven years of hands-on working experience in the manufacturing sector in Asia, the Middle East & Africa.

Certified CI practitioner, trainer, mentor, and lean thinker with in-depth knowledge of practicing with a track record of successfully implementing CI methodologies and tools like – Creating model Gemba, Organisational goal alignment (KRA & KPI), Operational waste analysis & reduction, Value Stream Mapping (VSM), Inventory reduction (up to 55%), TPM-OEE improvement (up to 90%), TQM-defect reduction (up to 85%), Methods & approach for RCA/Problem solving, SMED & SMIR-changeover time reduction (up to 85%), Operational cost reduction (up to 25%), in various (medium and large scale) industries in Africa

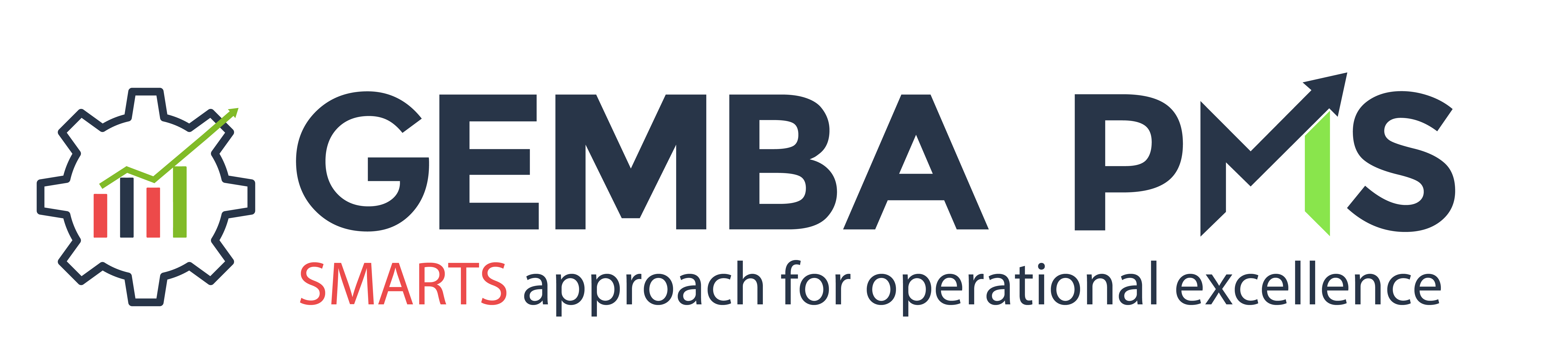

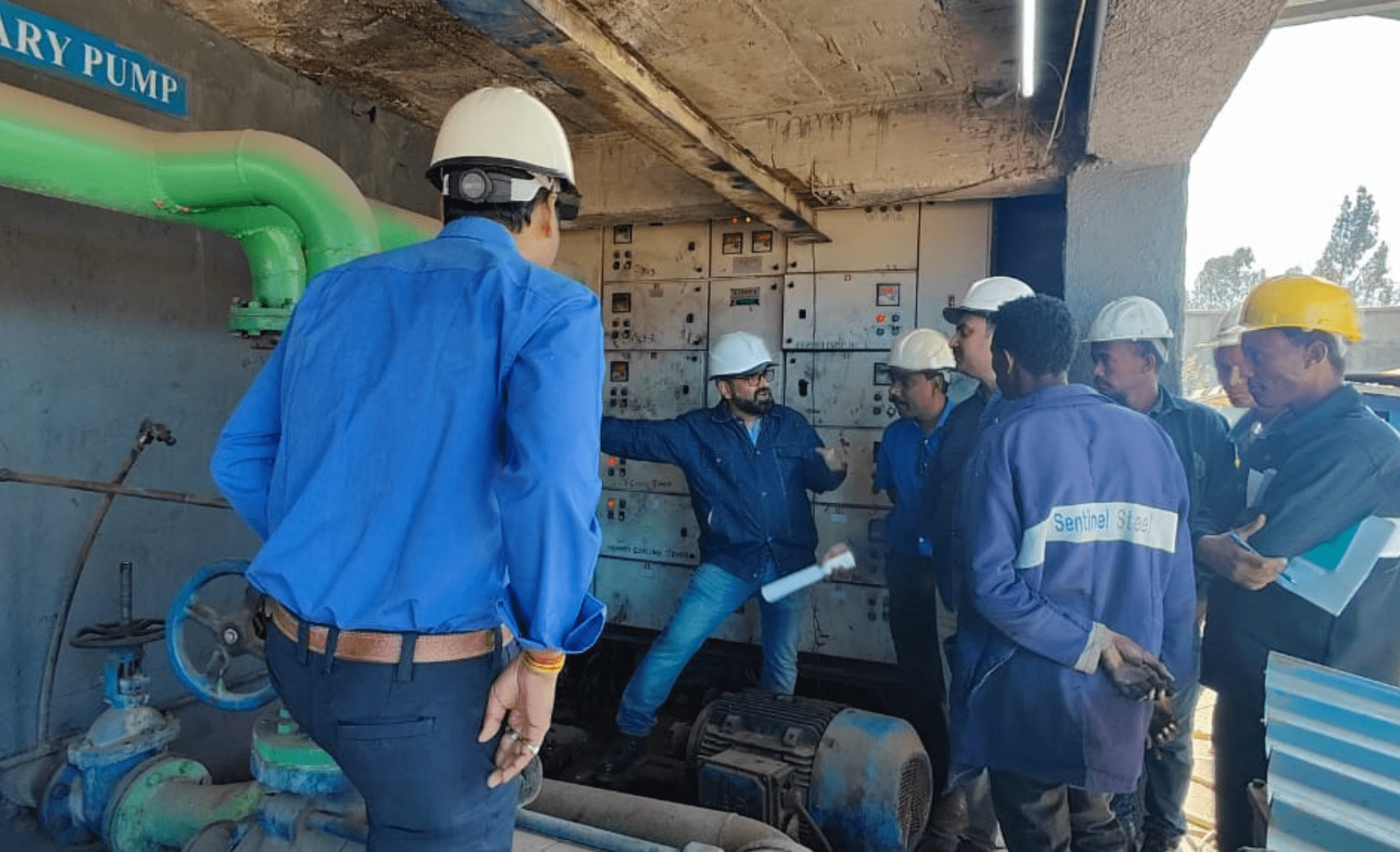

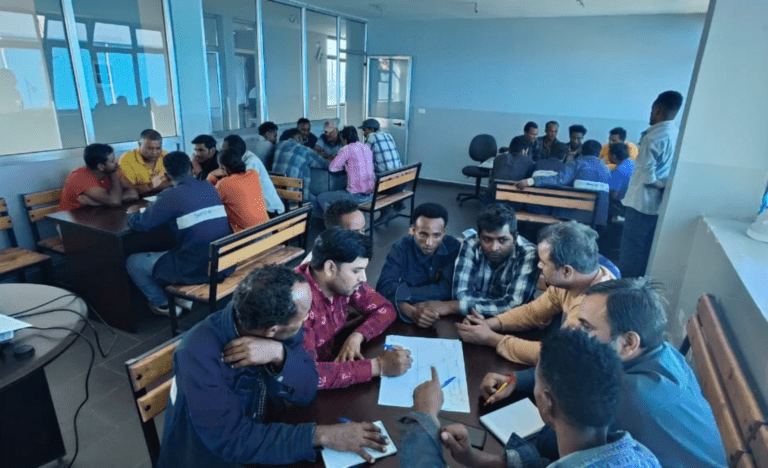

Gemba PMS On-Site

20 KEYS GLOBAL TEAM NETWORK